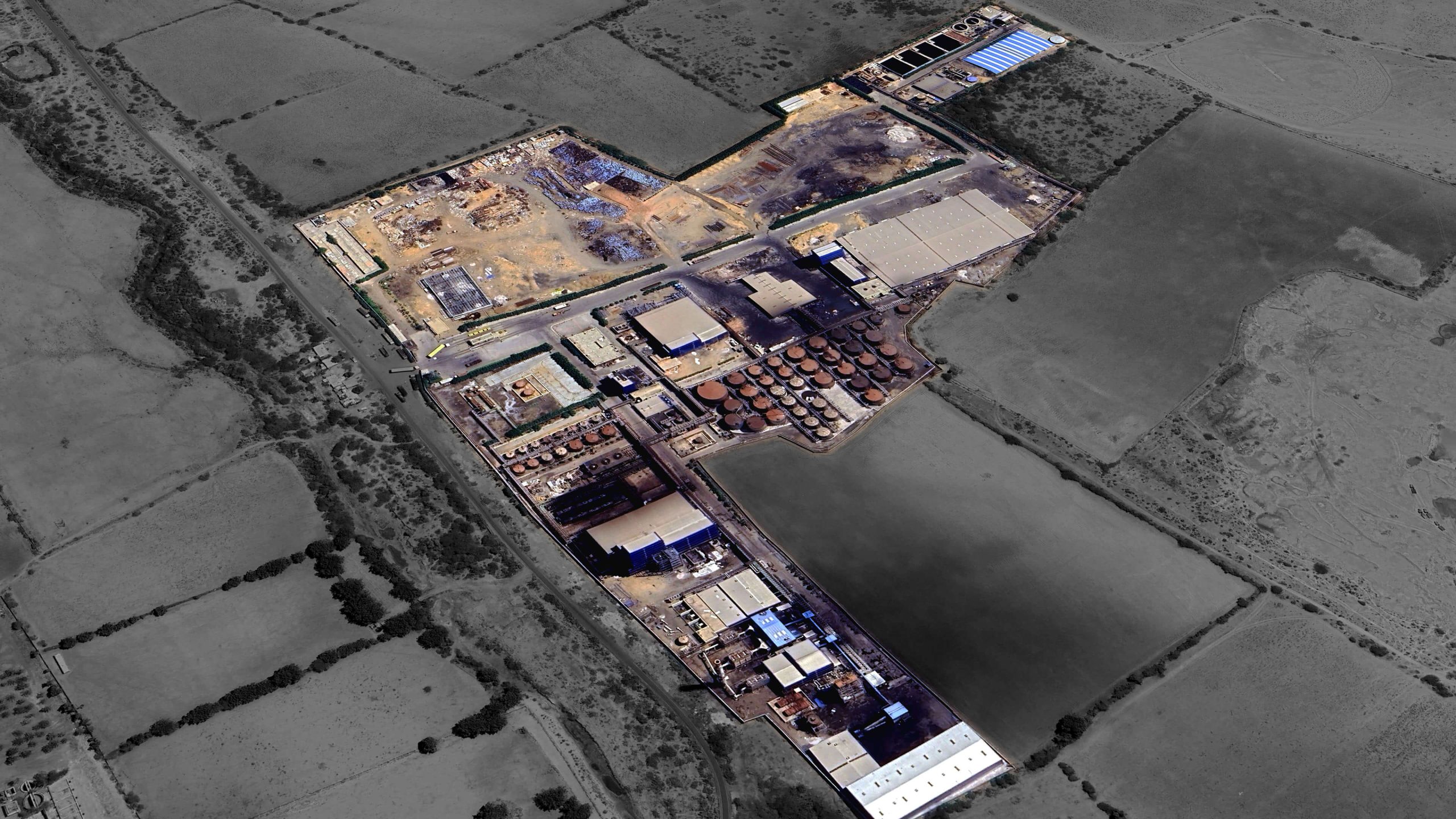

Sheel Oil Refinery

Kutch, Gujarat

Sheel Oil Refinery Kutch, Gujarat The Sheel Oil Refinery at Anjar is a state-of-the-art facility developed for Sheel Oils, a trusted name in the production of edible oils, oleo-chemicals, vanaspati, specialty fats, and bakery fats products. Known as one of India’s leading manufacturers in the industry, this facility showcases advanced infrastructure and robust engineering to…